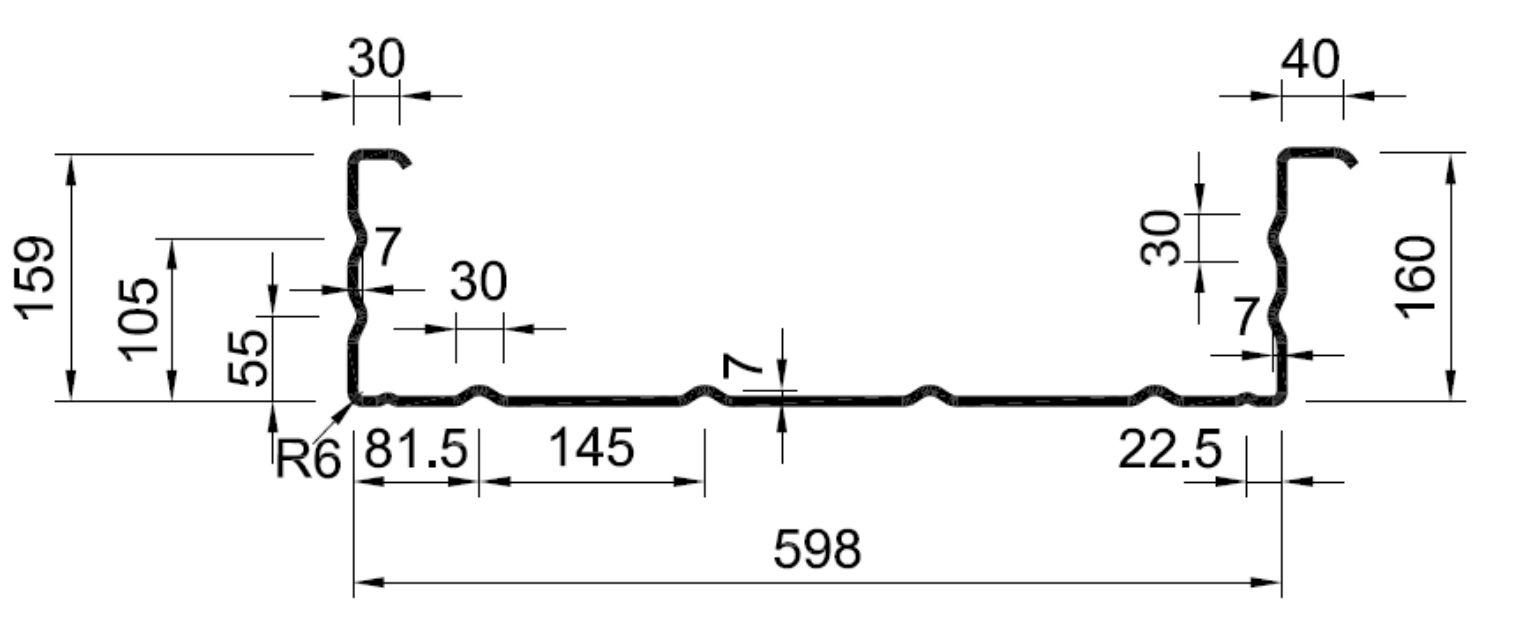

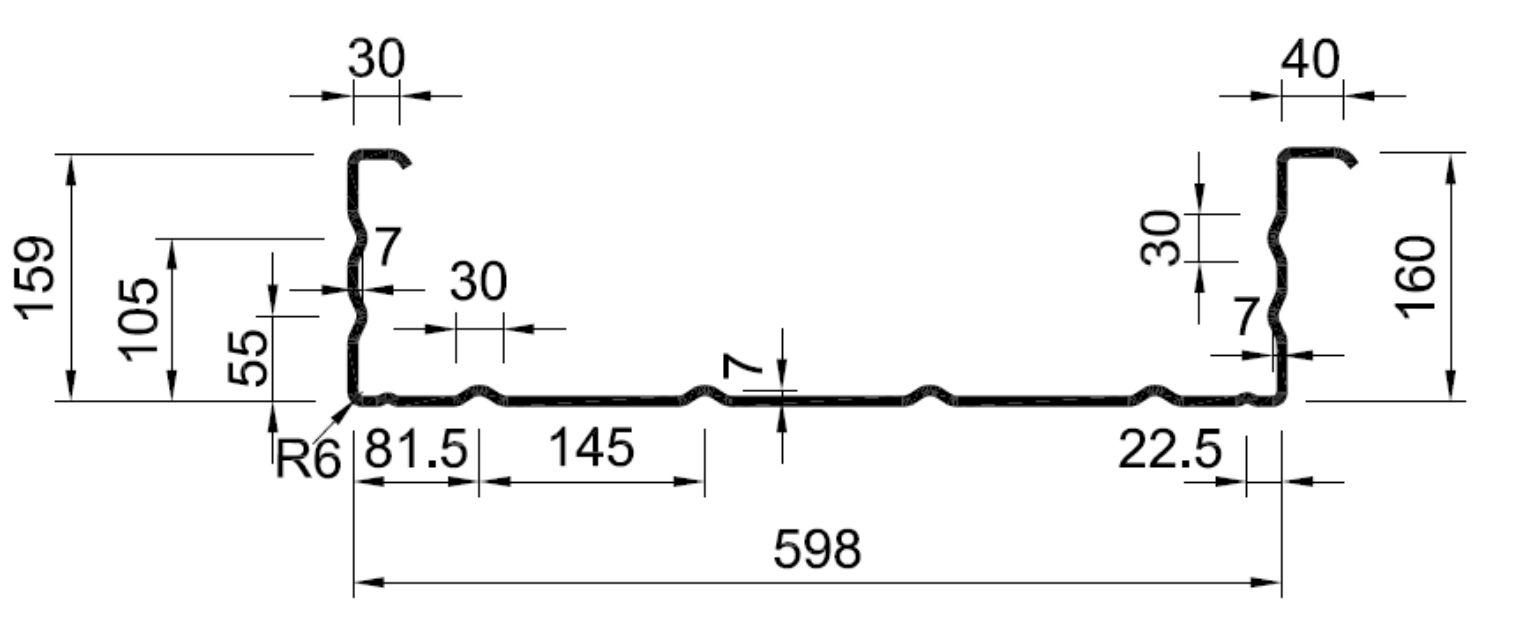

Hacierba 160/600 SR

Hacierba 160/600 SR1 Section properties of the liner tray in compliance with

baustatische Typenprüfung Bescheid Nr. T18-013

Hacierba 160/600 SR

Hacierba 160/600 SR

Nominal thickness = 0.88 mm Design thickness = 0.84 mm

Yield strength fy,k = 320 N/mm^2

Second moment of area Ief = 376.4 cm^4/m

Characteristic capacity of the liner tray for UDL downwards

Width of the end support bA = 40 mm Width of the internal support bB = 100 mm eps = 1

Mc,Rk,F = 6.96 kNm/m Rw,Rk,A = 10.15 kN/m Vw,Rk = 23.03 kN/m

M0,Rk,B = 14.08 kNm/m R0,Rk,B = 30.69 kN/m Mc,Rk,B = 8.54 kNm/m Rw,Rk,B = 18.63 kN/m

Width of the end support bA = 40 mm Width of the internal support bB = 300 mm eps = 1

Mc,Rk,F = 6.96 kNm/m Rw,Rk,A = 10.15 kN/m Vw,Rk = 23.03 kN/m

M0,Rk,B = 12.38 kNm/m R0,Rk,B = 77.75 kN/m Mc,Rk,B = 9.72 kNm/m Rw,Rk,B = 25.62 kN/m

Characteristic capacity of the liner tray for UDL upwards

Mc,Rk,F = 9.08 kNm/m Rw,Rk,A = 10.15 kN/m Vw,Rk = 23.03 kN/m

M0,Rk,B = 11.73 kNm/m R0,Rk,B = 39.53 kN/m Mc,Rk,B = 8.32 kNm/m Rw,Rk,B = 19.92 kN/m

Symbols (elements of capacity)

Mc,Rk,F Sagging moment capacity maxMR,Rk residual moment capacity

Rw,Rk,A External support capacity Vw,Rk Shear force

M0,Rk,B Hogging moment capacity under the assumption of no shear force

R0,Rk,B Internal support capacity under the assumption of no moment

Mc,Rk,B Hogging moment capacity Rw,Rk,B Internal support capacity

eps 1: linear interaction for M and R 2: quadratic interaction for M and R

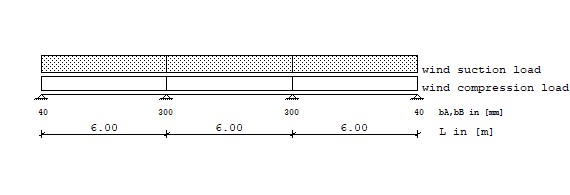

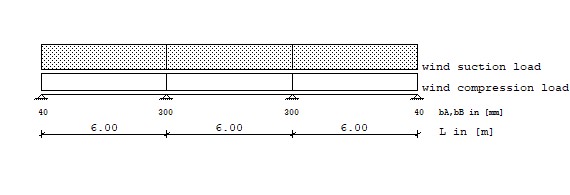

2 Structural system and loads

Loads Type 1: Trapezodial distributed load from a to a+b

Type 2: Pointload at a

Load Type q1 Start q2 Length

[kN/m^2] [m] [kN/m^2] [m]

wd Wind compression load 1 0.400 0.000 0.400 6.000

1 0.400 6.000 0.400 6.000

1 0.400 12.000 0.400 6.000

ws Wind suction load 1 -0.480 0.000 -0.480 6.000

1 -0.480 6.000 -0.480 6.000

1 -0.480 12.000 -0.480 6.000

3 Design of liner trays in compliance with German Standard "DIN EN 1993-1-3 (EC3)"

3.1 Ultimate limit state (ULS) elastic-elastic

3.1.1 Sagging moment gamma-F,G= 1.35 gamma-F,Q= 1.50 gamma-M= 1.10

Load combination Bay MEd Mc,Rd,F Utilization

[-] [-] [kNm/m] [kNm/m] [-]

1.50*Wd 1 1.728 < 6.327 0.273

2 0.540 < 6.327 0.085

3 1.728 < 6.327 0.273

1.50*Ws 1 -2.074 < 8.255 0.251

2 -0.648 < 8.255 0.078

3 -2.074 < 8.255 0.251

3.1.2 Reaction at end support gamma-F,G= 1.35 gamma-F,Q= 1.50 gamma-M= 1.10

Load combination Support FEd Rw,Rd,A Utilization

[-] [kN/m] [kN/m] [-]

1.50*Wd 1 1.440 < 9.227 0.156

4 1.440 < 9.227 0.156

1.50*Ws 1 -1.728 < 9.227 0.187

4 -1.728 < 9.227 0.187

3.1.3 Shear force at internal support gamma-F,G= 1.35 gamma-F,Q= 1.50 gamma-M= 1.10

Load combination Support VEd Vw,Rd bv Utiliz.

[-] [kN/m] [kN/m] [-] [-]

1.50*Wd 2 -2.160 < 20.936 0.091 0.103

1.50*Wd 3 2.160 < 20.936 0.091 0.103

1.50*Ws 2 2.592 < 20.936 0.091 0.124

1.50*Ws 3 -2.592 < 20.936 0.091 0.124

3.1.3 Reaction at internal support gamma-F,G= 1.35 gamma-F,Q= 1.50 gamma-M= 1.10

Load combination Support FEd Rw,Rd,B Utilization

[-] [kN/m] [kN/m] [-]

1.50*Wd 2 3.960 < 23.291 0.170

1.50*Wd 3 3.960 < 23.291 0.170

1.50*Ws 2 -4.752 < 18.109 0.262

1.50*Ws 3 -4.752 < 18.109 0.262

3.1.4 Hogging moment gamma-F,G= 1.35 gamma-F,Q= 1.50 gamma-M= 1.10

Load combination Support MEd Mc,Rd,B Utilization

[-] [kNm/m] [kNm/m] [-]

1.50*Wd 2 -2.160 < 8.836 0.244

3 -2.160 < 8.836 0.244

1.50*Ws 2 2.592 < 7.564 0.343

3 2.592 < 7.564 0.343

3.1.5 Combined check for bending and reaction gamma-F,G=1.35 gamma-F,Q=1.50 gamma-M=1.10

Load combination Support MEd/M0,Rd,B + (FEd/R0,Rd,B)^eps Utiliz.

[-] [-] [-] [-]

1.50*Wd 2 0.192 + 0.056 0.248

3 0.192 + 0.056 0.248

1.50*Ws 2 0.243 + 0.132 0.375

3 0.243 + 0.132 0.375

3.1.5 Combined check for bending and shear gamma-F,G=1.35 gamma-F,Q=1.50 gamma-M=1.10

Load combination Support MEd/Mc,Rd,B + (2*VEd/V,Rd,B-1)^2

[-] [-] [-] [-]

1.50*Wd Design not necessary!

1.50*Ws Design not necessary!

3.2 Serviceability limit state (SLS) elastic - elastic

3.2.1 Deflection gamma-F,G= 1.00 gamma-F,Q= 1.00 gamma-M= 1.00

Load combination Bay f Perm. f, L/150 Utilization

[-] [-] [cm] [cm] [-]

wd, Wind compression load 1 0.451 < 4.000 0.113

2 0.034 < 4.000 0.009

3 0.451 < 4.000 0.113

ws, Wind suction load 1 -0.751 < 4.000 0.188

2 -0.057 < 4.000 0.014

3 -0.751 < 4.000 0.188

The design of the liner tray is ok. The load capacities of the liner trays can have large

differences from manufacturer to manufacturer. Therefore, it is important that the liner tray

listed herein is actually installed on-site during construction.

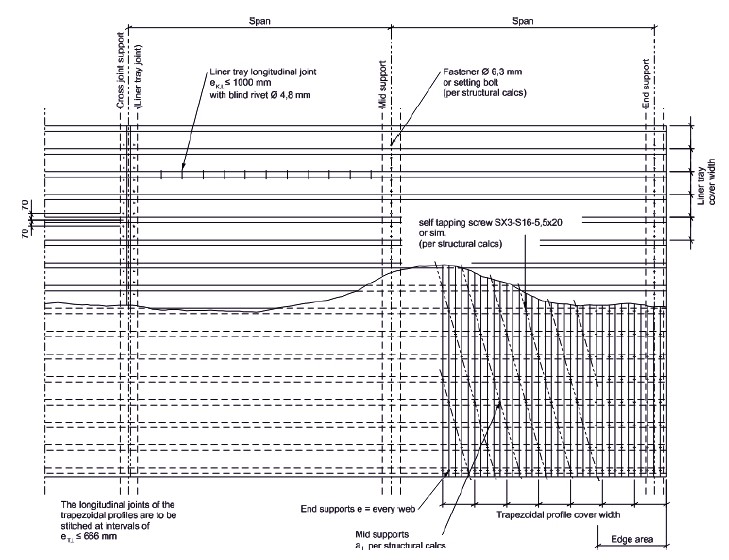

The upper chords of the liner trays must be stitched to the trapezoidal sheets at intervals

of al <= 621 mm centres.

The liner tray webs have to be stitched to each other in the longitudinal joints using blind

rivets or equally suitable alternative fixings at intervals of ek,l <= 1000 mm, at the same

time the longitudinal joints of the trapezoidal sheets must be stitched together at intervals

of et,l <= 666 mm.

The minimum requirements of the external shell are to be taken from the certification

baustatische Typenprüfung Bescheid Nr. T18-013. The proof of the structural integrity of

the external shell is not part of these calculations.

4 Design of connection elements

4.1 Connection of liner tray to substructure

Loads Type 1: Trapezodial distributed load from a to a+b

Type 2: Pointload at a

Load Type q1 Start q2 Length

[kN/m^2] [m] [kN/m^2] [m]

Ws, wind suction load 1 -0.600 0.000 -0.600 6.000

1 -0.600 6.000 -0.600 6.000

1 -0.600 12.000 -0.600 6.000

Characteristic forces of connection elements:

End support Fz,k= 3.600 kN NR,k,red= 0.7*NR,k= 2.520 kN VR,k= 3.600 kN

Internal support Fz,k= 3.600 kN NR,k,red= 0.7*NR,k= 2.520 kN VR,k= 3.600 kN

Shear and tension capacity of the connection elements, gamma= 1.33:

End support Fz,d= 1.895 kN VR,d= 2.707 kN

Internal support Fz,d= 1.895 kN VR,d= 2.707 kN

Reaction at the support, load case excluding safety factors:

Support Rv,k(wd) Rv,k(ws) Rv,k(option.) Descript. Rh,k(option.) Descript.

[-] [kN/m] [kN/m] [kN/m] [-] [kN/m] [-]

1 0.960 -1.440 0.000 0.000

2 2.640 -3.960 0.000 0.000

3 2.640 -3.960 0.000 0.000

4 0.960 -1.440 0.000 0.000

Reaction at support for load combinations:

Load combination Support Vertical Horizontal

[-] [kN/m] [kN/m]

1.5*Ws 1 -2.160 0.000

1.5*Ws 2 -5.940 0.000

1.5*Ws 3 -5.940 0.000

1.5*Ws 4 -2.160 0.000

Design check for connecting elements, module width bR = 600 mm

Support nVerb NE,d NR,d VE,d VR,d Utilization

[-] [-] [kN] [kN] [kN] [kN] [-]

1 2 0.648 < 1.895 0.000 < 2.707 0.342

2 2 1.782 < 1.895 0.000 < 2.707 0.940

3 2 1.782 < 1.895 0.000 < 2.707 0.940

4 2 0.648 < 1.895 0.000 < 2.707 0.342

Rv, Rh : Reaction at support caused by load combinations

nVerb : Number of connecting elements

bR : Module width

NE,d : Applied tension force in the connecting element = Rv·1/nVerb·bR·(-1)

NR,d : Tension capacity in the connecting element

VE,d : Applied shear force in the connecting element = Rh·1/nVerb·bR

VR,d : Shear capacity in the connecting element

4.2 Liner tray longitudinal joint

The liner tray webs have to be stitched to each other in the longitudinal joints using

blind rivets or equally suitable alternative fixings at intervals of ek,l <= 1000 mm.

4.3 Connection of trapezoidal sheets to the upper chords of the liner trays

The upper chords of the liner trays must be stitched to the trapezoidal sheets at inter-

vals of al <= 732 mm centres. The structural proof of these fixings is not part of this cal-

culation and must be provided separately when dimensioning the trapezoidal sheeting.

4.4 Example of a connection plan for a liner tray wall

5 Summary of design

Ultimate limit state (ULS) elastic-elastic

Mc,Rk,f 27.3 %

Rw,Rk,A 18.7 %

Rw,Rk,B 26.2 %

Vw,Rk 12.4 %

Mc,Rk,B 34.3 %

M-R 37.5 %

Serviceability limit state (SLS) elastic - elastic

Rw,Rk,B -

Mc,Rk,B -

M-R -

f 18.8 %